Web Tension

Web tension force systems are used in the paper, steel and associated industries to control the tension in the paper “web” on a dynamic basis. Because the paper web runs at high speed, tension control is essential to the production process to ensure, on the one hand, that the paper does not break and, on the other hand, that it is tight and does not tangle in the machinery. They are used, for instance, in the paper industry, paper winders / unwinders, printing presses and strip tension in continuous furnaces.

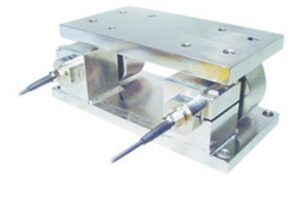

LTT – Low Tension

• Capacity range: 20, 50, 100, 200, and 500 lbs @ 2 Mv/V

• Alignment marks for measurement of resultant force

• Repeatability better than 0.02% rated output

• Minimal deflection allows high operating speeds

• Stainless steel construction with high overload capability

APPLICATIONS:

Winders/unwinders, Coaters, Laminators, Printing

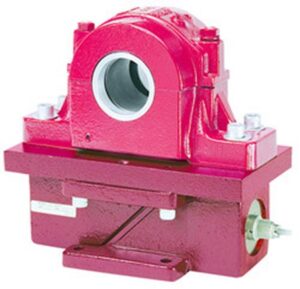

GLT – Web Tension

• Capacity range: 20, 50, 100, 200, and 500 Lbs at 2 Mv/V

• Full Wheatstone bridge design eliminates drift and recalibration

• Accommodates shaft misalignment up to 3°

• Rugged, compact size with high overload capability

• Measures low resultant tension forces with small wrap angles

• Scribe marked for precise alignment with resultant tension force

• Simple installation with pillow block or frame mounting

• Temperature compensated, FM and CSA approved

APPLICATIONS:

Winders/unwinders, Coaters, Laminators, Printing

Z1P – Web Tension

• Capacity range 2 Kn to 200 Kn (based on SNL bearing series)

• Vertical and/or horizontal web tension force measurement

• Low profile— minimal change in line profile when retrofitting existing equipment

• Units can be customized to fit existing applications

APPLICATIONS:

• Mining conveyors • Paper machines • Steel strip tension equipment • Felts, dryers, calendars, coaters/laminators • Winders and rewinders

FMU – Tension Module

• Capacity range FMU-1 2 Kn to 200 Kn, FMU-5 100 Kn- 400 Kn

• Measure full resultant web tension force

• Superior accuracy for heavy rolls with small wrap angles

• Vertical and/or horizontal web tension force measurement

• Low profile— minimal change in line profile when retrofitting

• Units can be customized to fit existing applications

APPLICATIONS:

• Winders and rewinders • Paper machines • Steel strip tension equipment • Mining conveyors • Felts, dryers, calendars, coaters/laminators

PST – Tension Module

• Accuracy better than 0.1% of the maximum strip tension

• Insensitive to side load forces

• Non sensitive to thermal expansion of the deflecting roller

• Based around standard KIS loadcells, low spare part cost

• Easy maintenance and calibration as a result

• Custom design adapted to existing bearing blocks

APPLICATIONS:

Strip tension in continuous furnaces for hot galvanizing and annealed lines.

HTZ-3 – Tension Module

• Capacity range: 500, 1K, 2K, 5K, 10K, 20K and 50Klb @ 2 mV/V

• Rugged stainless steel ‘I’ beam sensing section

• Resultant forces measure in the up or down direction

• FM and CSA approved

APPLICATIONS:

Paper machines, Roofing shingle manufacturing, Printing presses, Laminator, Dryer, Coating zones, Felt measurement

G4 – Tension Transmitter

The G4 can be programmed to monitor multiple tension zones.

Function blocks can be set up to monitor 1,2 or 4 load cells per roll.

Display, total, side and difference depending on configuration.

Analog outputs or PLC interfaces available.

8 total inputs to select how you want to monitor your tension zones.

Contact IWSystems to assist with configuring your tension control.